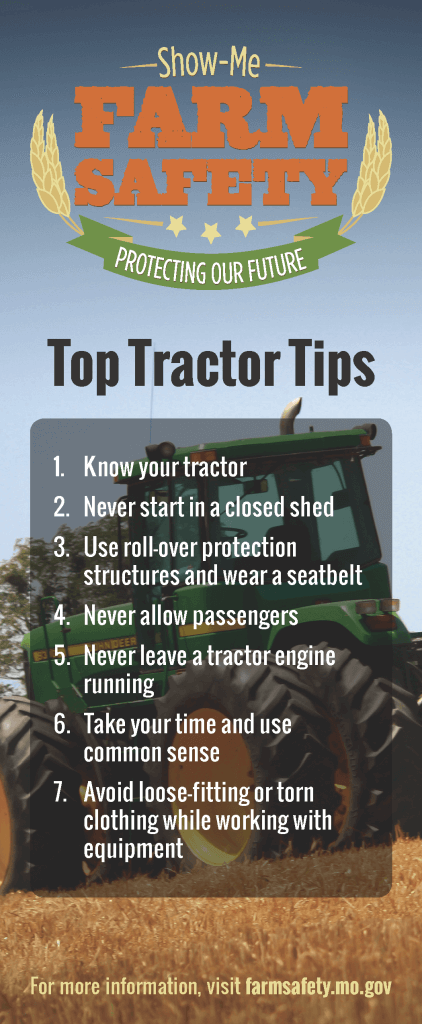

Tractors

Tractors are essential to many daily tasks on the farm. Although we use tractors frequently, it’s important to keep the tractor in good working condition and not to push the boundaries when it comes to operating or repairing the tractor.

Rollovers account for a large majority of tractor fatalities, and can happen in a matter of seconds. There are two types of rollovers: a rearward rollover and a sideways rollover. A rearward rollover occurs when a tractor tips to the rear when the rear wheels cannot rotate enough to move the machine forward. A sideways rollover can happen when a tractor turns too sharply or on too steep of an incline. The wider the tractor, the more stable the machine is.

Rearward tractor rollovers can be prevented by:

- Avoiding driving on steep hillsides

- Backing the tractor up steep hills

- Changing tractor speed gradually by applying power smoothly

- Properly stabilizing the tractor for the work to be done

- Using tire chains, boards and other materials to improve traction of wheels

- Hitching loads to the drawbar correctly

Sideway rollovers can be prevented by:

- Properly stabilizing the tractor

- Avoiding driving on steep hillsides

- Avoiding turning at excessive speeds

- Avoiding driving too close to the edge of roadside ditches or slopes

- Using a tractor equipped with a Roll-Over Protection Structure

Roll-Over Protection Structures (ROPS) are operator compartment structures (usually cabs or frames) on the tractor. The Roll-Over Protection System, which includes the structure and proper seat belt use, can eliminate nearly all fatalities caused by rollovers. If you have an older tractor model that does not have a cab or frame, a Roll-Over Protection Structure can be retrofitted to your tractor. Many companies provide engineer-certified Roll-Over Protection Structures for purchase and installation. For low-clearance environments, like orchards or inside buildings, equipment should feature AutoROPS, which stay in a lowered position until a rollover condition is detected, and then extends into a locked position.

Before moving a tractor, you should be sure the area is clear. An unseen child or adult near the tractor is at risk of being run over. Children should not be permitted to play where tractors and other machinery are running. You should always drive tractors at a safe speed, especially near populated areas.

We often rely on repair methods taught to us by our parents and grandparents without reading the operator’s manual. Be familiar with the safety features of your tractor and any heavy equipment before using. Have you lost your manual or never had one? Find the tractor manual for the model you need.

It’s critical to keep your tractor current with safety features as they become available. This includes stability, tractor safety decals, operator comfort and control and protection from other hazards.

Guided by your operator’s manual, set up a daily maintenance routine to check:

- Engine oil and hydraulic fluid levels

- Radiator coolant level

- Brakes and brake fluid

- Tire pressure

- Fan belts

Check to ensure implements are secure and properly connected. Check carefully for hydraulic leaks by using a piece of cardboard or wood rather than your hands.

Loose-fitting clothing is easily caught in the moving parts of tractors and other equipment. Wear fitted pants, tuck in any loose shirt tails, and avoid wearing scarves when working on or around machinery. Protect your feet by wearing sturdy work shoes or boots with non-skid soles and steel toe caps. Heavy work gloves and safety glasses may also be useful when working with machinery.

Many tractor-related injuries occur as a result of falling while mounting or dismounting the steps of the tractor. The steps on the tractor should be used like the steps of a ladder; either two hands and one foot or one hand and two feet should be in contact at all times. Be sure your pant cuffs or boot loops are clear of the pedals when you exit the tractor to prevent tripping or falling.

Do not carry extra riders on heavy machinery, unless it is equipped with a buddy seat. To keep all riders safe, there should only be as many passengers on the tractor as there are seat belts. Accidents can happen, even from cabs with locked doors.

Avoid starting a tractor or equipment while standing outside the cab or on the ground. An operator who starts a tractor while standing on the ground cannot be sure if the transmission is in neutral or park. When a manual transmission is in gear when the engine is started, the tractor could run over the operator because the tractor will start moving as soon as the engine turns over. If your tractor does not have a shield covering the starter motor, retro-fit shields are available to prevent by-pass starting. This shield should not be removed from the starter motor except when servicing the starter motor, then replaced immediately.

Front-end loaders are often misused by stretching their lifting capacity and inappropriate use. Adequate counter-balancing of a loader-equipped tractor is needed for safe lifting. When moving big round bales, it’s important to use front-end loaders equipped with grapple forks to help grip the bale and prevent it from rolling out of the bucket and down the arms of the loader toward the driver. Another front-loader option is a spear-type bale mover, mounted on either the front or rear of the tractor.

Always keep the speed low when using the front-end loader and NEVER use the loader to lift people.