Handling & Storing Grain

Grain handling and storage play a vital part in Missouri farming. Increased storage capacities combined with larger, faster handling and automated equipment contribute to the industry’s high hazard level. While new technologies have increased efficiency on the farm, the machinery also gives farmers the ability to work alone—exposing them to additional dangerous situations.

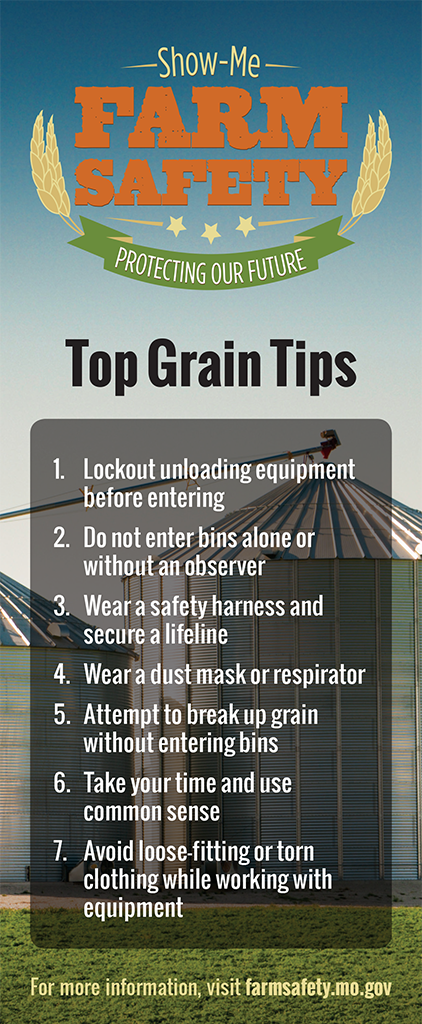

Do not enter bins while grain is being loaded or unloaded. Suffocation is one of the most common causes of death involving grain bins. This occurs when someone enters a bin with flowing grain and is pulled under and covered with grain. Many farmers underestimate the massive force behind flowing grain. Standing on moving grain can be deadly; the grain works like quicksand to create suction that can bury a person in seconds. Wait until the dust clears so you can clearly see your footing before entering.

Be sure to turn off and lock out all power equipment associated with the grain when not in operation, including the augers used to help move grain. Be especially aware of automatic unloading equipment, and keep children away from operating grain augers at all times.

Fermentation produces carbon dioxide, a colorless, odorless gas. Grain bins often have an oxygen-deficient atmosphere. Working in a grain bin where carbon dioxide is present can be very harmful to your health. To reduce the hazard, open all manholes and doors to force air through the bin before working inside. Once exposed, the carbon dioxide can get in your bloodstream and slow down your breathing, which can cause drowsiness, headaches and even death by suffocation. Even a small amount of spoiled grain can produce millions of tiny mold spores which easily become airborne when disturbed. Airborne mold spores can be inhaled, causing reactions so severe that sometimes hospitalization is necessary. Farmers working without respiratory protection inside a bin or other grain storage facility where moldy grain is present are especially vulnerable to mold and dust reactions. Your tolerance may be reduced with each repeated exposure to dust and mold. Be sure to wear a mask that fits securely around your mouth and nose to protect you. Fumigants are incredibly toxic to humans when swallowed, inhaled or even absorbed through the skin. Be sure to follow all label recommendations when in use. It is necessary to only use masks and equipment tested by the National Institute for Occupational Safety and Health when fumigating. Always run the ventilation fan before entering a bin to reduce the danger of the environment to your health. To ensure the safety of those near the bin, post warning signs telling people you are fumigating grain and to avoid the area. Some producers choose a safer and more effective method and have their stored grain fumigated by a licensed, professional fumigator.

Grain augers become increasingly dangerous with each hour of use. It is important to continuously review the operator’s manual and examine all equipment parts to make sure the auger is in safe operating condition. Equipment guards and shields prevent opportunities for farmers and workers to become entangled in moving equipment parts. Removing equipment guards and not replacing them is a common cause of injury in farmers. When repairing machinery, be sure to replace all guards and shields when finished to reduce injury. It is extremely important to make sure there is a guard on a PTO-driven grain auger. Some PTO shafts can rotate at 540 revolutions per minute, which can cause severe injury and even death. The power shaft that moves power to the top of the auger can cause the same injuries as a rotating PTO shaft. Always replace damaged or missing PTO and power shaft shields before operation. Intake screens on augers help prevent your hands and feet from getting caught between during operation. Today, most new augers are sold with intake screens in place. If you have an older machine that does not have an intake screen; add one, and be sure to replace missing or damaged screens. Many grain augers operate on a belt or chain drive system. These belts and chains have several pinch points. A pinch point is where a belt or chain wraps onto a pulley or sprocket. If a finger or piece of clothing gets caught in a pinch point or the auger, it may result in severe injury, sometimes requiring amputation. Most of these systems do not come with shields, but they can be easily fabricated for use.

Before working in bins, be sure to have all equipment in place in case of emergency. This includes full-body harnesses and life lines for easier rescue in case of a grain avalanche. This also includes installing rest platforms every 30 feet on vertical ladders on the outside of bins to reduce the risk of falls while climbing the bins. Strategically placing safety decals around the grain bins should alert workers to the possible dangers of flowing grain, crusted-over grain and carbon dioxide.